Introduction to Coconut Shell Charcoal Briquettes

Trong những năm gần đây, the demand for sustainable and eco-friendly fuel alternatives has surged, making Bánh than than vỏ dừa a highly sought-after product. Derived from Vỏ dừa, these briquettes are not only an excellent renewable energy source but also a profitable business opportunity. TạiMáy móc Weiwa, we specialize in providing efficient coconut shell charcoal briquette making production lines that transform waste coconut shells into high-quality charcoal briquettes with minimal environmental impact.

Why Choose Coconut Shell for Charcoal Production?

Coconut shells are a rich, carbon-dense biomass material that makes an excellent raw material for charcoal production. Unlike traditional wood charcoal, coconut shell charcoal offers several advantages:

- High Fixed Carbon Content: Ensures a longer burn time and higher energy output.

- Low Ash & Smoke Emission: Makes it cleaner and more environmentally friendly.

- Durable & Dense Structure: Ideal for briquetting without excessive binding agents.

- Waste Utilization: Converts agricultural waste into a valuable commodity.

Given these benefits, Bánh than than vỏ dừa are widely used in BBQs, hookahs, industrial heating, and even as activated carbon.

Dây buộc sản xuất than củi Coconut Shell

CácDây chuyền sản xuất than than vỏ dừa involves several key stages, each crucial for producing high-quality briquettes efficiently. Below is a detailed breakdown of the entire workflow:

1. Raw Material Collection & Pre-Treatment

The process begins with collecting dry coconut shells, preferably those that have been sun-dried or mechanically dried to reduce moisture content (ideally below 15%). Proper drying ensures better carbonization efficiency and reduces energy consumption in later stages.

- Nghiền nát (Optional): If the shells are too large, mộtmáy nghiền or hammer mill may be used to break them into smaller pieces for uniform carbonization.

2. Cacbon hóa – Turning Shells into Charcoal

Cáccarbonization process is the heart of charcoal production, where coconut shells are heated in an oxygen-free environment to decompose organic matter into charcoal.

In the video, rice husks are used as an example

Working Principle of Carbonization:

In the following video, we take rice husks as an example

- Coconut shells are fed into a lò cacbon hóa (rotary kiln, brick kiln, or continuous carbonizer).

- The furnace is heated to 300–600°C in an oxygen-deprived chamber (to prevent combustion).

- Over 4–8 hours, the shells undergo Phân vùng, releasing volatile gases and leaving behind solid charcoal.

TạiMáy móc Weiwa, we offer Thiết bị cacbon hóa nâng cao that maximizes yield while minimizing emissions.

3. Nghiền nát & Grinding the Charcoal

The resulting Charcoal vỏ dừa is brittle and needs to be crushed into fine powder (usually 3–5 mm or finer) for briquetting.

- Acharcoal crusher or hammer mill is used to break down the charcoal into a consistent size.

- Proper particle size ensures better binding and uniform briquette formation.

4. Mixing with Binder (Optional)

While some processes use binder-free briquetting, many manufacturers add a natural binder (VÍ DỤ., starch, molasses, or clay) to improve cohesion.

- The binder is mixed with the charcoal powder in a mixing drum to ensure even distribution.

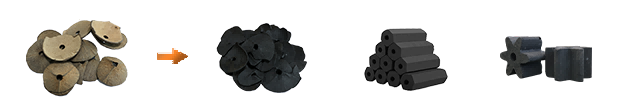

5. Briquetting – Forming the Briquettes

Cácbriquetting process compresses the charcoal powder into đồng phục, dense briquettes using high pressure.

How Briquetting Works:

- Cáccharcoal-binder mixture is fed into a Máy nướng máy (usually a screw press or hydraulic press).

- Under áp suất cao (50–100 MPa), the mixture is molded into cylindrical, quảng trường, or oval briquettes.

- No additional glue is needed if the charcoal has sufficient natural binding properties.

TạiMáy móc Weiwa, của chúng tôicoconut shell briquette machines are designed for Hiệu quả cao, Tiêu thụ năng lượng thấp, and durable performance.

6. Drying the Briquettes

Freshly pressed briquettes contain high moisture (10–20%) and must be dried to ensure hardness and long shelf life.

- Natural Sun Drying: Slow but cost-effective (takes 2–3 days).

- Mechanical Drying (Hot Air Dryer): Faster (6–12 hours) and more controlled, ensuring consistent moisture levels below 8%.

7. Bao bì & Storage

Once dried, the briquettes are:

- Cooled to room temperature.

- Packaged in bags or sacks for storage and distribution.

- Stored in a dry place to prevent moisture absorption.

Working Principles of the Coconut Shell Charcoal Briquette Production Line

The entire production line operates on a systematic flow, ensuring hiệu quả, chất lượng, and minimal waste.

Key Principles:

- Thermal Decomposition (Cacbon hóa): Converts biomass into charcoal via controlled pyrolysis.

- Mechanical Compression (Briquetting): Uses high pressure to form dense briquettes without binders (or with minimal binders).

- Moisture Control (Sấy khô): Ensures briquettes are hard, bền, and long-lasting.

Của chúng tôiWeiwa Machinery equipment is engineered to optimize each stage, reducing energy waste and maximizing output.

Market Potential & Business Opportunities

Cácglobal demand for coconut shell charcoal briquettes is growing rapidly due to:

1. Eco-Friendly Fuel Alternative

- Used in households, Nhà hàng, and industries as a cleaner alternative to wood or coal.

- Preferred for hookahs, Shisha, and BBQs due to its aroma and clean burn.

2. Activated Carbon Industry

- Coconut shell charcoal is a prime raw material for activated carbon, used in water filtration, Tinh chế không khí, and medical applications.

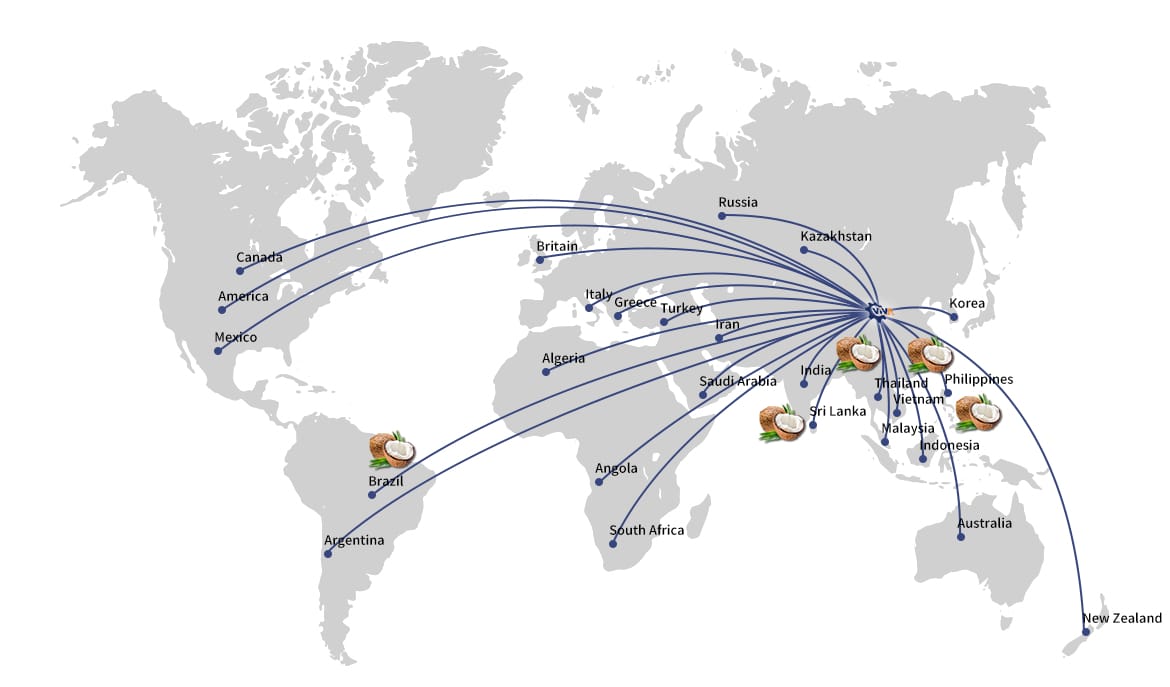

3. Export Potential

- Countries like Japan, Korea, Europe, and the Middle East import high-quality coconut shell briquettes in bulk.

4. Government Support & Sustainability Trends

- Many governments promote biomass energy projects, offering subsidies or tax incentives for charcoal producers.

By investing in a coconut shell charcoal briquette making production line, entrepreneurs can tap into a lucrative, eco-friendly, and high-demand market.

Why Choose Weiwa Machinery for Your Production Line?

TạiMáy móc Weiwa, we are a leading manufacturer of biomass processing equipment, specializing in coconut shell charcoal briquette production lines. Here’s why we are your best choice:

✅High-Quality Equipment – Our carbonizers, crushers, Máy nướng máy, and dryers are built for durability and efficiency.

✅Customizable Solutions – We design turnkey production lines tailored to your production scale.

✅Energy-Efficient Technology – Our machines minimize energy consumption and emissions.

✅Global Expertise – We have supplied equipment to qua 50 quốc gia, ensuring reliable support and after-sales service.

✅Competitive Pricing – Get premium machinery at factory-direct prices with flexible payment options.

Start Your Coconut Shell Charcoal Briquette Business with Weiwa Machinery

Cáccoconut shell charcoal briquette making production line is a profitable, sustainable, and in-demand business. With the right equipment and process, you can convert waste coconut shells into high-value charcoal briquettes for domestic and international markets.

Máy móc Weiwa provides complete, đáng tin cậy, and efficient production solutions to help you succeed in this industry. Whether you’re a small-scale entrepreneur or a large manufacturer, we have the right equipment and expertise to support your venture.

Liên hệ với chúng tôi ngay hôm nay to get a free consultation, Trích dẫn, or equipment demo for your Dây chuyền sản xuất than than vỏ dừa.

Về Máy móc Weiwa

Máy móc Weiwa is a professional manufacturer of biomass processing equipment, specializing in máy làm than, briquette presses, carbonization furnaces, và hệ thống sấy khô. Vớiyears of experience and a global customer base, we are committed to providing innovative, energy-efficient, and cost-effective solutions for sustainable energy production.

Let us help you turn coconut shells into profit—partner with Weiwa Machinery today!

WeChat

WeChat

+8613838093177

+8613838093177