Hoàn toàn tự động Dây chuyền sản xuất briquette than than là một hệ thống hiệu quả cao được thiết kế để chế biến than than hoặc than thành những viên than bánh đồng nhất với sự can thiệp thủ công tối thiểu. Dây chuyền sản xuất than than than được sử dụng rộng rãi trong các ngành công nghiệp như than BBQ, sản xuất nhiên liệu, luyện kim, và chế biến hóa học. Máy làm bánh than than này sử dụng công nghệ tự động hóa nâng cao, và có thể đạt được hoạt động hoàn toàn tự động từ chế biến nguyên liệu thô đến xả thành phẩm.

Đặc điểm dây chuyền sản xuất than than than

Đúc hiệu quả: Máy nướng hoàn toàn tự động được sử dụng để đảm bảo đúc đồng đều, Cải thiện mật độ sản phẩm và khả năng chống ngọn lửa.

Hoạt động thông minh: Tự động cho ăn, Nhấn và truyền tải, giảm can thiệp thủ công và cải thiện hiệu quả sản xuất.

Thích ứng đa đặc điểm: Khuôn có thể được điều chỉnh để tạo ra những quả bóng carbon có kích thước và hình dạng khác nhau để đáp ứng các nhu cầu đa dạng.

Charcoal briquette làm cho các lợi thế

Hàng đầu ngành: Kiểm soát tự động thông minh, giảm chi phí lao động bằng cách 30%;

Bóng than chất lượng cao: Độ chính xác đúc cao, Kháng lửa kéo dài, không dễ phá vỡ;

Khả năng tương thích đa mục đích: Thích hợp cho nhiều loại nguyên liệu thô như than, Bột than, Bột khoáng, vân vân.;

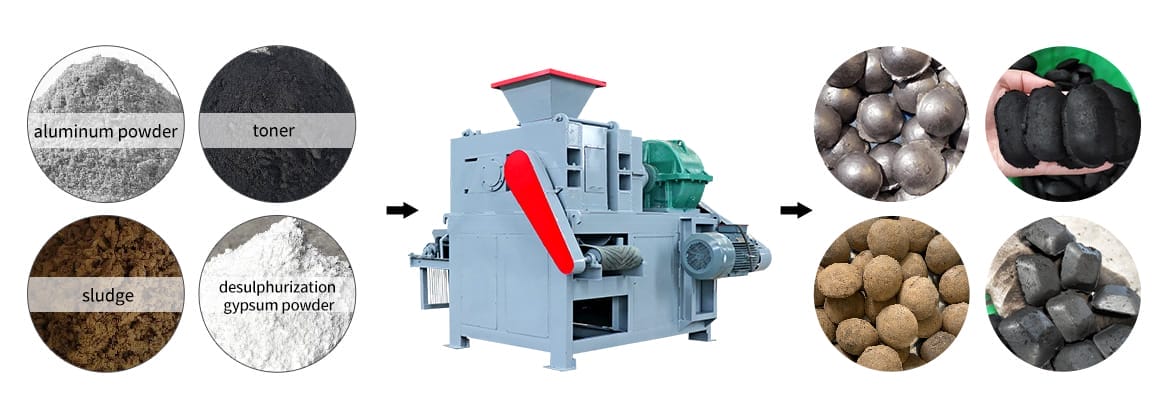

Charcoal Ball Briquette làm nguyên liệu thô & Sản phẩm cuối cùng

Dây chuyền sản xuất briquette của Ball Ball có một loạt các nguyên liệu thô,chẳng hạn như khúc gỗ, cây tre , Vỏ dừa, vỏ cọ, Chip gỗ, trấu gạo, Vỏ đai ốc, vỏ quả óc chó và các nguyên liệu thô sinh khối khác nhau. Máy làm bánh than than phù hợp cho các nhà máy chế biến than, Các công ty sản phẩm than, và các nhà sản xuất nhiên liệu thân thiện với môi trường, những người cần thiết bị sản xuất than than hiệu quả và ổn định để tăng sản xuất và giảm chi phí lao động.

Các lĩnh vực áp dụng than

Charcoal được làm bởi dây chuyền sản xuất than nướng than với thời gian cháy dài, Giá trị nhiệt lượng cao, Không có khói, Không có vụ nổ, Bảo vệ môi trường và kinh tế. Charcoal có thể được sử dụng để đốt trong nước, nồi hơi, thịt nướng, sưởi ấm lò sưởi, nhà máy điện và các khía cạnh khác.

Ngoài ra, Do cấu trúc vi mô độc đáo và khả năng hấp phụ siêu, Nó được sử dụng rộng rãi trong nhiều lĩnh vực như thực phẩm, Dược phẩm, công nghiệp hóa chất, luyện kim, Quốc phòng, nông nghiệp và bảo vệ môi trường.

Dòng sản xuất briquette than briquette

Trong quá trình sản xuất, Các nguyên liệu thô được nghiền đầu tiên và được sàng lọc để đảm bảo các hạt gỗ đồng nhất;

Sau đó, Chúng được trộn và điều hòa với nước để đạt được điều kiện cấp bách tối ưu;

Sau đó, Các chip gỗ được hình thành thành các quả bóng than tiêu chuẩn bởi một máy ép bánh rổ;

(Trong quá trình này, Nhiệt độ và áp suất có thể được kiểm soát chính xác theo nhu cầu để đảm bảo sự ổn định của chất lượng sản phẩm hoàn chỉnh)

Cuối cùng, Các quả bóng than đã hoàn thành được đóng gói thông qua một hệ thống truyền tải tự động và sẵn sàng bán;

Máy sản xuất than briquette

A. Máy nghiền được phân chia là một thiết bị nghiền gỗ quy mô lớn để nghiền cành, Rễ cây, mẫu, Pallet gỗ, đồ nội thất chất thải, gỗ đóng đinh và các vật liệu khác.

B. Máy sấy trống là một trong những thiết bị sấy truyền thống, đáng tin cậy trong hoạt động, linh hoạt trong hoạt động, mạnh mẽ trong khả năng thích ứng, và khả năng xử lý lớn. Đường kính và chiều dài của thiết bị được xác định theo yêu cầu sấy.

C. Lò cacbon hóa liên tục là một loại máy cacbon hóa bột carbon mới thức ăn trong nguyên liệu thô và thải ra carbon hoàn thành. Nó thuộc về máy sấy và cacbon hóa loại nóng bên ngoài.

D.hammer Mill là một thiết bị nghiền tốt có thể xử lý tất cả các loại gỗ, mảnh vụn gỗ, cành, cành, Chip gỗ, Bảng trang trí, Vỏ cây, cây tre , vỏ cây tre và các nguyên liệu thô khác vào mùn cưa cùng một lúc.

E. WHOEL MILL MIXER là một mô hình kết hợp phay bánh xe và trộn được thiết kế theo những ưu điểm của thiết bị trộn và trộn bánh xe nước ngoài mới nhất. Thích hợp để trộn bột và vật liệu hạt, chẳng hạn như bột carbon, Bột than, Đất sét, bùn chịu lửa, cát đuôi, xỉ, Cát đúc, vân vân.

F.Adesive Trộn thùng được điều khiển bởi vành đai hình tam giác động cơ để điều khiển bánh công tác để xoay, và nước và chất kết dính được trộn hoàn toàn. Nó là một thiết bị cần thiết để tăng thời gian phản ứng của tác nhân và tăng cường chất lượng phản ứng của vật liệu.

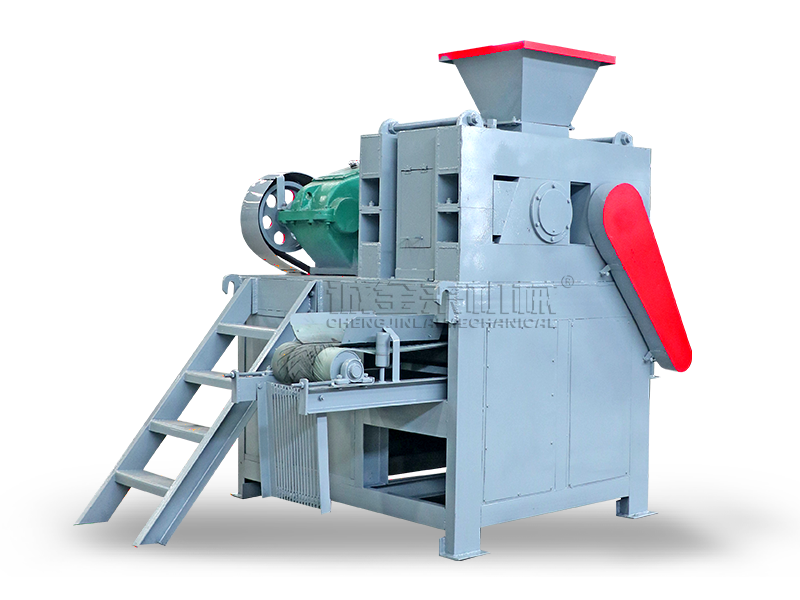

G.Charcoal Ball Briquette Machine là một thiết bị ép bột và vật liệu hạt vào đúc. Nó có thể nhấn bột khoáng khác nhau, Bột kim loại, Bột than, bột than cốc và các vật liệu khác để định hình chúng.

Máy sấy đai H.Mesh sử dụng không khí nóng làm môi trường sấy, và không khí nóng được gửi đến máy sấy thông qua quạt dự thảo cảm ứng để làm khô các vật liệu; Các vật liệu được xử lý được lật trong máy sấy thông qua chu kỳ nhiều lớp, và không khí nóng đi qua từ dưới đến trên đai lưới và lớp vật liệu được làm khô từng lớp để đạt được mục đích làm khô.

Chúng tôi cung cấp 100% Thiết kế dây chuyền sản xuất than đá miễn phí

Khi bạn có kế hoạch định cấu hình dây chuyền sản xuất briquette than than than, Vui lòng cho chúng tôi biết chi tiết của bạn.

Những vật liệu này bao gồm

1.Loại nguyên liệu thô, kích cỡ, Độ ẩm

2.Kích thước thực vật

3.Khả năng biến áp

4.Loại và kích thước của thành phẩm

5.Nhu cầu cho đầu ra

Càng chi tiết càng tốt, tốt nhất, Để tùy chỉnh thiết bị dây chuyền sản xuất than than than của riêng bạn, Và chúng tôi sẽ cung cấp cho bạn các sơ đồ lập kế hoạch trang web 3D miễn phí.

Các vật liệu khác nhau sẽ được thiết kế thành giải pháp sản xuất khác nhau, Khách hàng tại thời điểm tham vấn cần thông báo cho chúng tôi về các tài liệu’ Độ ẩm, Kích thước hạt, năng suất, Briquettes Kích thước, hình dạng, Một số trường hợp đặc biệt có thể cần thiết bị phụ trợ như các loại máy nghiền khác,các loại máy trộn khác,lưới màn hình, rây rung, Binder trung chuyển, Bể trộn chất lỏng, phân tách từ tính, Máy cân điện tử, Ổ đĩa tần số biến đổi.

Tóm lại, Dây chuyền sản xuất báo chí Ball Ball hoàn toàn tự động là một sự đổi mới quan trọng đã thúc đẩy việc hiện đại hóa ngành công nghiệp than. Hiệu quả cao và bảo vệ môi trường của nó đã khiến nó được ca ngợi rộng rãi trên toàn thế giới và trở thành một công cụ quan trọng để thúc đẩy phát triển bền vững. Nếu bạn cũng quan tâm đến dây chuyền sản xuất báo chí than này, Xin vui lòng để lại cho chúng tôi một tin nhắn trực tuyến để biết thêm thông tin chi tiết!!

Bài viết liên quan

WeChat

WeChat

+8613838093177

+8613838093177