Giới thiệu: The Growing Demand for Sustainable Charcoal in Africa

Africa, đặc biệt là Zimbabwe, đối mặt với một thách thức năng lượng quan trọng: cân bằng áp lực phá rừng với nhu cầu gia tăng đối với nhiên liệu nấu ăn giá cả phải chăng. Sản xuất than truyền thống, thường không bền vững, đã dẫn đến suy thoái môi trường nghiêm trọng. Enter Máy móc Weiwa, một nhà đổi mới hàng đầu trong công nghệ chuyển đổi sinh khối, which recently conducted a successful sawdust charcoal making machine trial in Zimbabwe.

The Science Behind Sawdust-Based Charcoal Production

Why Sawdust? A Renewable Alternative to Wood

Sawdust, một sản phẩm phụ của ngành công nghiệp gỗ thịnh vượng của Zimbabwe, là một nguồn tài nguyên không được sử dụng. Không giống như sản xuất than truyền thống, mà phụ thuộc vào cây bị chặt, sawdust charcoal making machines convert waste into high-energy fuel briquettes. Của chúng tôisawdust extruder in Zimbabwe compresses sawdust into dense, burnable logs without the need for chemical binders, making it an eco-friendly alternative.

The Role of Carbonization in Biomass Conversion

The process begins with cacbon hóa—heating sawdust in a low-oxygen environment to remove volatile compounds, leaving behind pure carbon. Của chúng tôicharcoal making machine in Zimbabwe integrates this step seamlessly, ensuring high yields and minimal emissions.

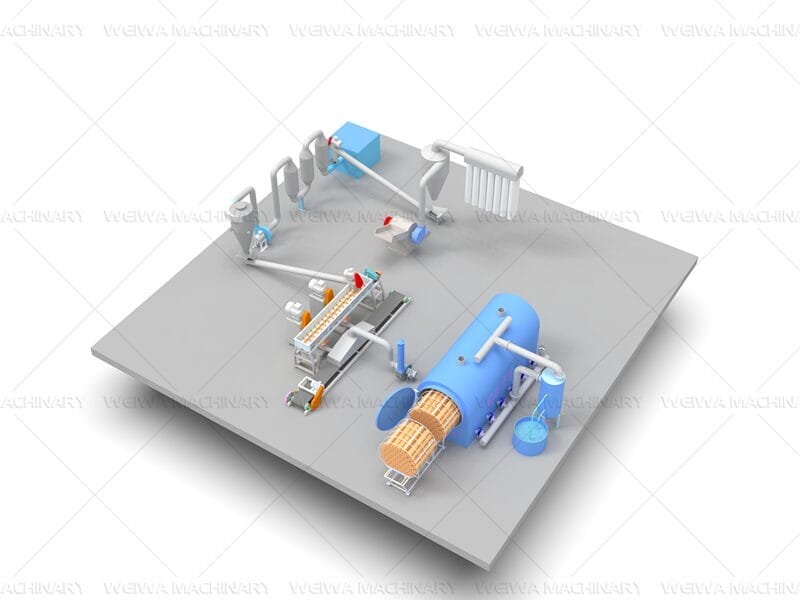

Weiwa’s Sawdust Extruder Production Line: Các tính năng chính & Trial Results

1. High-Efficiency Extrusion Technology

Của chúng tôisawdust extruder is designed to handle Zimbabwe’s diverse biomass feedstock, including eucalyptus and pine sawdust. Trong thời gian xét xử, the machine achieved:

- Extrusion speed: 300 kg/hour

- Tiêu thụ năng lượng: 0.06KWh/kg (lower than industry average)

2. Briquetting: Turning Extruded Sawdust into Fuel

The extruded sawdust is then fed into our Máy briquette than, which compresses it into uniform briquettes. The trial demonstrated:

- Briquette density: 1.2 g/cm³ (optimal for long burn time)

- Moisture content: <8% (ensuring quick ignition)

3. Carbonization Efficiency

Our integrated carbonization chamber reduced sawdust to charcoal with:

- Conversion rate: 35% (higher than traditional methods)

- Emissions: 40% lower than open-pit kilns

Why Zimbabwe Needs Weiwa’s Charcoal Solutions

Environmental Benefits

- Deforestation reduction: Replacing wood charcoal with sawdust-based briquettes could save Zimbabwe’s forests.

- Lượng khí thải thấp hơn: Our machines produce 50% fewer greenhouse gases than traditional methods.

Economic Advantages for Local Communities

- Job creation: Small-scale entrepreneurs can adopt our technology.

- Cost savings: Briquettes are 20% cheaper than firewood in rural areas.

Customer Feedback & Future Plans

Testimonials from Zimbabwean Partners

“Weiwa’s machine exceeded our expectations. The briquettes burn cleaner and longer than anything we’ve used before.” — Local Zimbabwean Distributor

Scaling Up: Weiwa’s Vision for Africa

We plan to establish regional service centers in Zimbabwe, Kenya, and South Africa to support our clients.

Về máy móc Weiwa

TạiWeiwa Machinery, we specialize in biomass conversion solutions, including sawdust extruders, MÁY BRIQUETE, Và complete production lines. Với hơn 15 nhiều năm kinh nghiệm, we’ve helped clients in Africa, Châu Á, and Latin America transition to sustainable fuel production. Our commitment to innovation and sustainability drives every project.

Liên hệ với chúng tôi ngay hôm nay to learn how our machines can transform your biomass waste into profitable, eco-friendly charcoal.

- Đám đông:+8613838093177

- WhatsApp:+8613838093177

- E-mail:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177