The Rising Demand for Charcoal Rod Machines in Malaysia & เอเชียตะวันออกเฉียงใต้

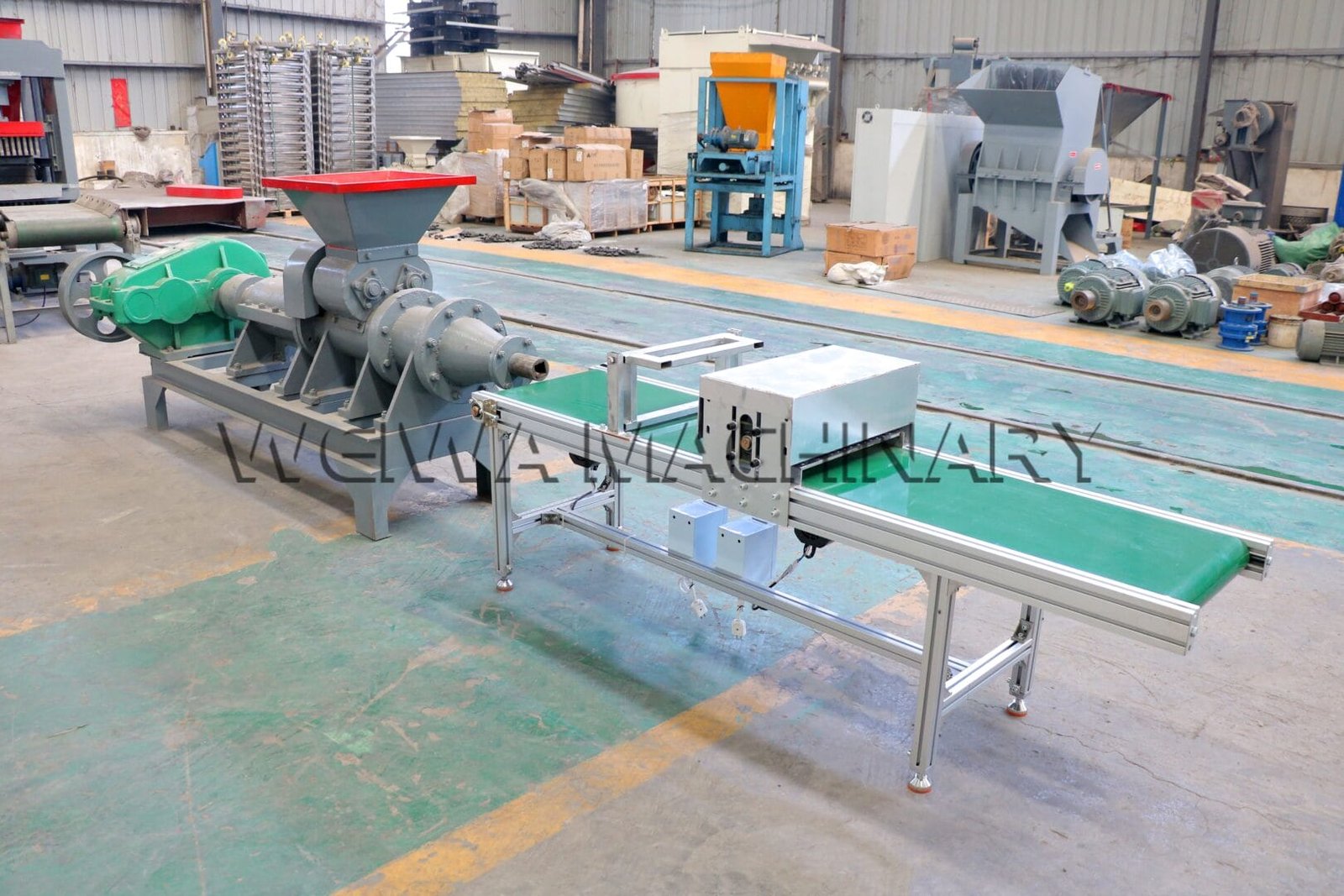

ในช่วงไม่กี่ปีที่ผ่านมา, Malaysia and Southeast Asia have seen a surge in demand for charcoal briquettes and rods, driven by the growth of BBQ culture, industrial heating, and eco-friendly fuel alternatives. ในฐานะผู้ผลิตชั้นนำ, เครื่องจักร Weiwa has been actively testing our เครื่องอัดรีดถ่านพร้อมเครื่องตัด and rod briquette machine with cutter in local conditions to optimize performance for Malaysian clients.

Why Cutter-Integrated Charcoal Machines Matter in Malaysia?

The Challenge: Manual Cutting vs. Automated Efficiency

Traditional charcoal extruder machines produce continuous rods that require manual cutting, leading to:

- Inconsistent lengths (affecting burning efficiency).

- Wasted raw materials (improper sizing).

- Slower production rates (labor-intensive).

ของเราCharcoal Extruder Machine with Cutter and Rod Briquette Machine with Cutter solve these issues by automatically slicing rods to precise lengths (เช่น, 40มม., 60มม., or custom sizes), การทำให้มั่นใจ:

Uniform burning performance

Higher output per hour

Reduced labor costs

Weiwa’s Cutter-Equipped Machine Field Test in Malaysia

Test Setup: ที่ตั้ง & Client Profile

We deployed our latest charcoal extruder with cutter at a Malaysian charcoal producer specializing in coconut shell briquettes. Their key requirements:

- High-capacity production

- Consistent rod diameter

- Minimal downtime.

Performance Highlights

- Seamless Cutting Mechanism

- The built-in cutter ensured zero jamming even with dense coconut shell charcoal.

- Adjustable speed control allowed custom-length rods (40mm–100mm) based on client needs.

- Faster Production & Labor Savings

- Before: Manual cutting required 2 workers → After: Fully automated, reducing manpower needs.

- Output increased by 30% without compromising quality.

- Durability in Tropical Conditions

- Malaysia’s high humidity posed no rusting issues, thanks to Weiwa’s powder-coated steel frame.

ราคาเครื่องทำถ่าน

A common concern among Malaysian clients is the ราคาเครื่องทำถ่าน. ในขณะที่cutter-equipped models may have a slightly higher upfront cost, long-term ROI is clear:

- Lower labor expenses (fewer workers needed).

- Reduced waste (precise cutting minimizes offcuts).

- Faster payback period (higher daily output).

Weiwa offers competitive pricing with customizable features (เช่น, diesel/electric motor options) to fit Malaysia’s budget ranges.

Why Weiwa’s Cutter-Integrated Machines Lead in Southeast Asia?

1. Localized Support & After-Sales Service

Unlike generic suppliers, เว่ยหวาจัดให้:

- On-site installation training in Malaysia.

- ความพร้อมของอะไหล่ within 72 hours.

2. Customization for Regional Needs

- Diameter adjustments (for coconut shell, ไม้, or biomass).

- Voltage compatibility (Malaysia’s 3-phase power systems).

3. Proven Track Record

Our machines are already operational in ประเทศมาเลเซีย, ประเทศอินโดนีเซีย, ประเทศไทย, and Vietnam, with 95% client retention.

Is a Cutter-Equipped Charcoal Machine Right for Your Business?

If you’re a Malaysian charcoal producer looking to:

✔ Boost efficiency (automated cutting).

✔ Reduce waste & labor costs.

✔ Sell premium, uniformly sized briquettes,

Then Weiwa’s Charcoal Extruder Machine with Cutter or Rod Briquette Machine with Cutter is the ideal solution.

Contact us today for a free consultation or live demo in Malaysia.

เกี่ยวกับ เครื่องจักร Weiwa

At เครื่องจักร Weiwa, we specialize in high-performance charcoal and briquette machines for global markets, including ประเทศมาเลเซีย, เอเชียตะวันออกเฉียงใต้, และต่อไป. ด้วยเกิน 30+ ประสบการณ์หลายปี, we provide:

Custom-designed machines (for coconut shell, ไม้, ชีวมวล).

On-site support & การฝึกอบรม.

ราคาที่แข่งขันได้ with fast ROI.

ของเราcutter-integrated charcoal extruders and rod briquette machines are trusted by hundreds of clients worldwide. Let’s discuss how we can optimize your production—get in touch today.

Wechat

Wechat

+8613838093177

+8613838093177