A New Chapter in Sustainable Biomass Utilization

On a bright morning at our Weiwa Machinery factory, the hum of forklifts and the coordinated efforts of our logistics team marked the beginning of an exciting journey—a custom-designed sawdust briquette production line was being prepared for shipment to Suriname, a vibrant country in northeastern South America. This isn’t just another delivery; it’s a testament to how advanced biomass technology is bridging continents to address energy needs, reduce waste, and foster sustainable development.

As a leading manufacturer specializing in sawdust extruder machines, sawdust briquette machines, and complete charcoal briquetting production lines, Weiwa Machinery has been at the forefront of helping clients across the globe transform agricultural and forestry residues into high-value charcoal products.

Suriname Is the Growing Demand for Biomass Charcoal in South America

Suriname, with its rich forest resources and agricultural activities, generates significant amounts of biomass waste annually, including sawdust from timber processing and crop residues from farming. ตามธรรมเนียม, much of this waste was either burned or discarded, contributing to environmental pollution and missed economic opportunities. อย่างไรก็ตาม, the tide is turning.

ในช่วงไม่กี่ปีที่ผ่านมา, Suriname has seen a rising interest in biomass charcoal production as a cleaner, more sustainable alternative to traditional wood charcoal. Unlike conventional charcoal, which often relies on unsustainable deforestation, biomass charcoal is made from renewable waste materials like sawdust, แกลบ, or coconut shells. This shift is driven by multiple factors:

- Environmental Concerns: Reducing deforestation and lowering carbon emissions.

- Energy Needs: Providing a cost-effective fuel source for households and industries.

- โอกาสทางเศรษฐกิจ: Creating jobs in rural areas through biomass collection and processing.

Our client in Suriname, a forward-thinking entrepreneur, recognized these benefits and reached out to Weiwa Machinery to establish a local production line. The result? A tailored sawdust briquette production line designed to meet their specific requirements, now en route to Suriname to kickstart a new era of sustainable charcoal making.

Inside the Shipment

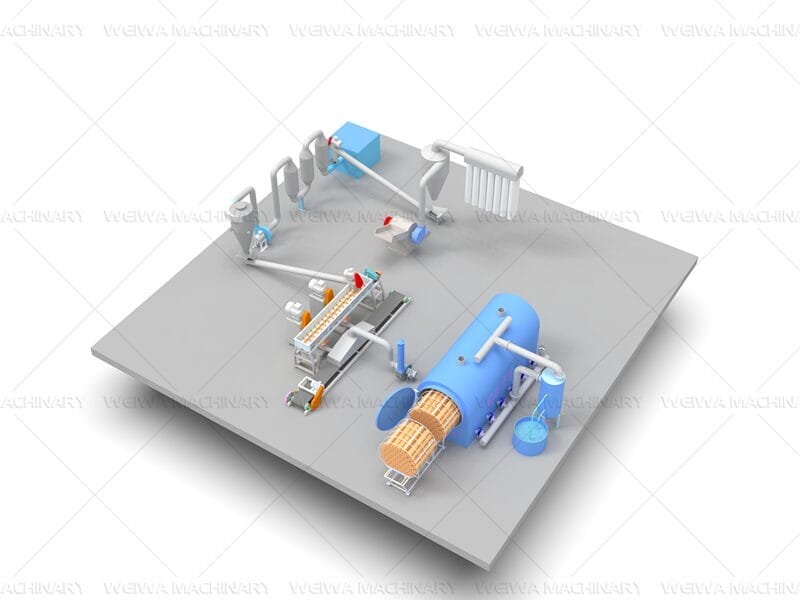

The shipment to Suriname includes a complete sawdust briquetting production line, with the sawdust extruder machine as its centerpiece. Let’s take a closer look at the core components that make this system a game-changer for biomass utilization:

The Sawdust Extruder Machine Is Heart of the Production Line

The sawdust extruder is the critical piece of equipment that transforms loose sawdust into dense, cylindrical briquettes. ที่ Weiwa Machinery, our sawdust extruder machines are engineered with precision to ensure high efficiency and durability. Here’s how it works:

- Raw Material Input: Loose sawdust, typically with a moisture content of 8-12%, is fed into the extruder.

- High-Temperature Compression: The extruder uses a combination of mechanical pressure and heat (generated by friction) to compress the sawdust into a dense form.

- Briquette Formation: The compressed sawdust is forced through a die, forming long, cylindrical briquettes that are then cut to the desired length.

What makes our sawdust extruder unique is its ability to handle various types of biomass materials, not just sawdust. Whether it’s rice husks, หอยมะพร้าว, or other agro-waste, the machine can be adjusted to produce high-quality briquettes tailored to local market needs.

The Complete Briquetting Production Line

Beyond the extruder, the shipment includes:

This integrated approach ensures that our clients in Suriname can produce charcoal briquettes with minimal manual intervention, maximizing productivity and profitability.

How Biomass Turns into Fuel?

Charcoal making is both an art and a science, especially when it comes to using biomass waste. Here’s a simplified breakdown of the process, highlighting the role of our sawdust briquette machine and sawdust extruder:

- Material Preparation: Sawdust or other biomass materials are collected, dried, and crushed to the right size. Moisture control is crucial—too much moisture leads to poor-quality briquettes, while too little can cause excessive dust.

- Extrusion and Briquetting: The prepared material is fed into the sawdust extruder, where it’s compressed into dense briquettes. The extruder’s heat and pressure activate the natural lignin in the biomass, acting as a natural binder to hold the briquette together without the need for additional chemicals.

- การทำให้เป็นคาร์บอน (Optional): While the briquettes can be used directly as fuel, they can also undergo carbonization (heating in a low-oxygen environment) to produce charcoal with higher calorific value and longer burn time.

The beauty of this process lies in its sustainability. By using waste materials like sawdust, we’re not only reducing environmental pollution but also creating a renewable energy source that benefits both producers and consumers.

Why South America Needs Sustainable Charcoal Solutions?

South America, with its diverse ecosystems and growing population, faces unique challenges in balancing development with environmental conservation. Countries like Suriname, Brazil, and Colombia are increasingly turning to biomass charcoal as a solution to:

- Reduce Deforestation: Traditional charcoal production often relies on cutting down native forests, threatening biodiversity. Biomass charcoal, made from waste materials, offers a sustainable alternative.

- Support Rural Economies: Biomass collection and processing create jobs in rural areas, empowering local communities.

- Promote Clean Energy: Biomass charcoal produces fewer emissions compared to traditional charcoal, contributing to better air quality and public health.

Our shipment to Suriname is part of a larger trend. Across South America, entrepreneurs and governments are recognizing the potential of biomass charcoal to drive sustainable development. By providing reliable, high-quality equipment like our sawdust extruder machines and sawdust briquette machines, Weiwa Machinery is proud to be a partner in this journey.

Our Commitment to Quality and Customer Support

Shipping a production line to Suriname isn’t just about sending equipment—it’s about building a long-term partnership. ที่ Weiwa Machinery, we’re committed to ensuring our clients succeed, from the initial consultation to post-installation support.

Here’s what sets us apart:

- โซลูชันที่กำหนดเอง: Every client’s needs are unique. We work closely with our customers to design production lines that match their raw materials, production goals, and budget.

- Quality Assurance: Our sawdust extruder machines and sawdust briquette machines are built with durable materials and undergo rigorous testing to ensure reliability.

- การสนับสนุนทั่วโลก: From installation guidance to troubleshooting, our team is always available to assist clients, no matter where they are in the world.

For our Suriname client, this means not only receiving a top-notch production line but also having access to our expertise to ensure smooth operations and maximum returns on investment.

A Shared Vision for a Sustainable Future

As the shipment of our sawdust briquette production line makes its way to Suriname, we’re filled with excitement and anticipation. This project isn’t just about exporting equipment; it’s about sharing knowledge, fostering innovation, and supporting sustainable development in South America.

The sawdust extruder machine at the heart of this production line symbolizes the transformative power of technology. It takes what was once considered waste and turns it into a valuable resource, benefiting both the environment and local economies.

ที่ Weiwa Machinery, we believe that sustainable charcoal making is not just a trend—it’s the future. By working with clients like our Suriname partner, we’re helping to build a world where clean energy, reduced waste, and economic growth go hand in hand.

เกี่ยวกับ เครื่องจักร Weiwa

Weiwa Machinery is a leading manufacturer of biomass processing equipment, specializing in sawdust extruder machines, sawdust briquette machines, and complete charcoal briquetting production lines. จบด้วย 30 ประสบการณ์หลายปี, we’ve served clients in over 50 ประเทศ, helping them transform agricultural and forestry waste into high-value products.

Our mission is simple: to provide reliable, efficient, and customized solutions that empower our clients to succeed in the biomass industry. Whether you’re looking to start a small-scale briquette production line or a large-scale industrial operation, Weiwa Machinery is your trusted partner.

Contact us today to learn more about our equipment and how we can help you achieve your biomass goals. ด้วยกัน, let’s build a greener, more sustainable future.

Wechat

Wechat

+8613838093177

+8613838093177