Weiwa Machinery specializes in advanced charcoal production technology, offering reliable equipment that transforms biomass waste into high-quality charcoal with excellent efficiency and low emissions. Our machines are designed for different scales of production, ensuring flexibility for both small workshops and large industrial plants. With robust structure, energy-saving systems, and simple operation, Weiwa charcoal making machines are widely applied in processing sawdust, bamboo, नारियल के गोले, चावल की भूसी, and other agricultural residues into value-added charcoal products.

To meet the diverse needs of global customers, Weiwa provides three main charcoal production solutions:

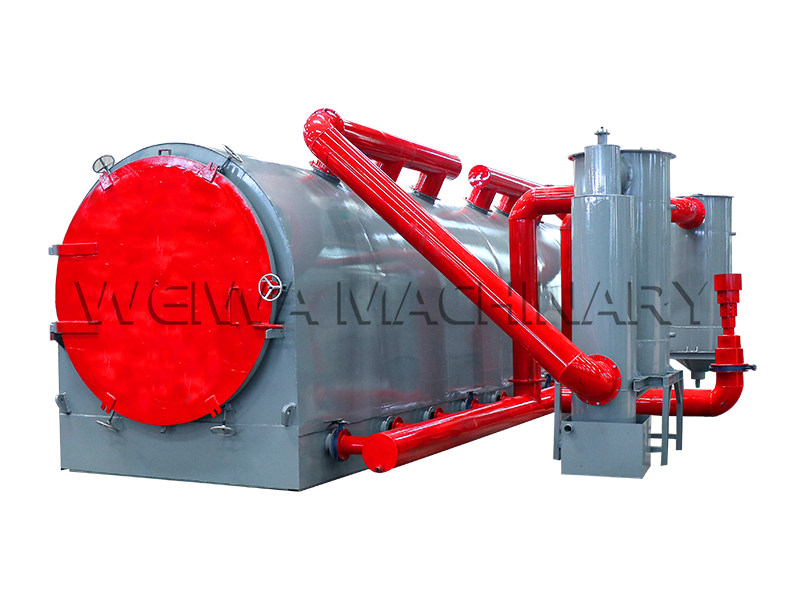

निरंतर कार्बनकरण भट्ठी – Ideal for large-scale operations, delivering uninterrupted output and stable performance with advanced heat utilization.

क्षैतिज कार्बोज़ाइजेशन भट्टी – A versatile and cost-effective design suitable for batch processing, ensuring high carbonization rates with easy maintenance.

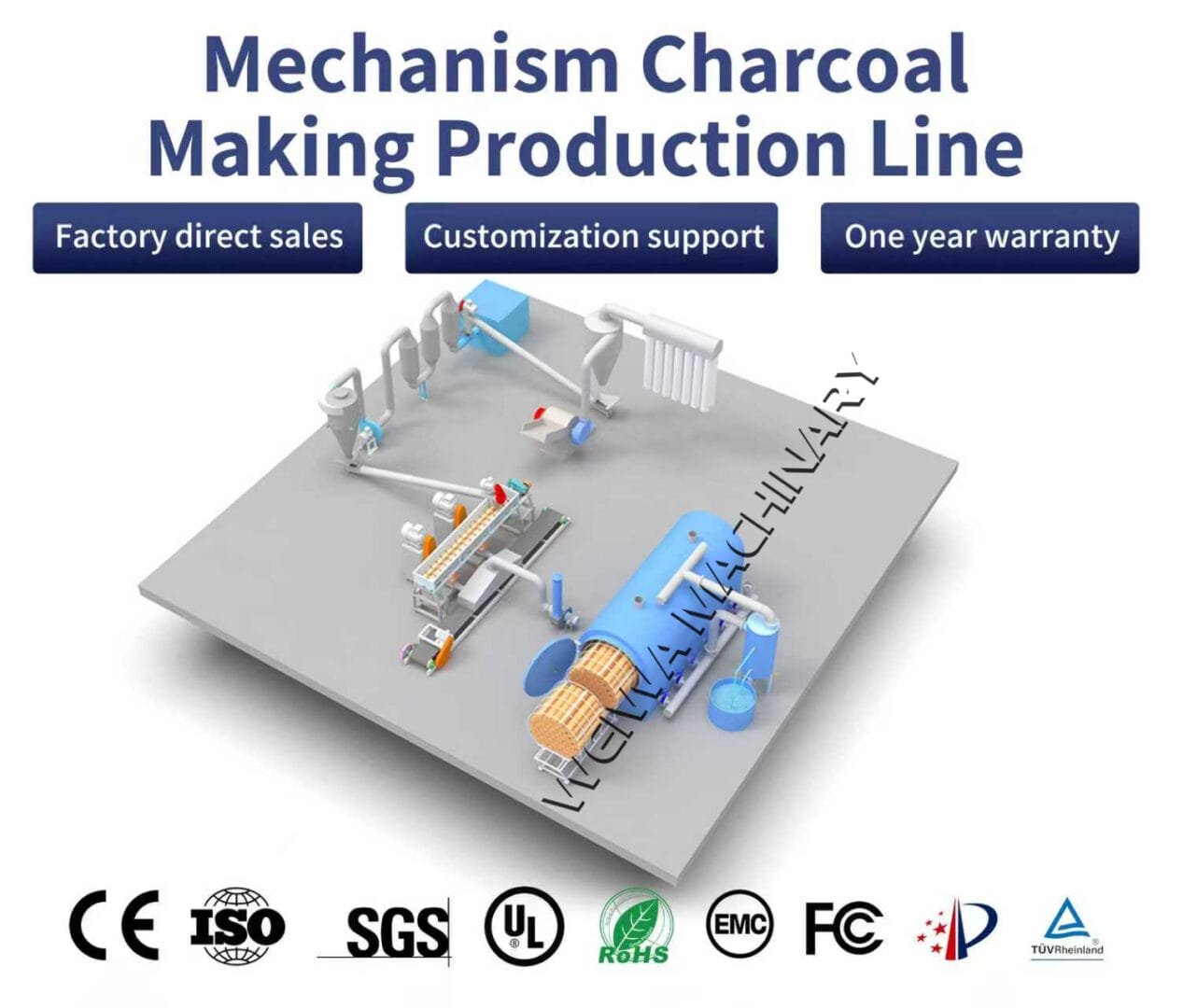

Mechanism Charcoal Making Production Line – A complete turnkey solution that integrates crushing, सुखाने, कड़ा, and carbonization for commercial charcoal production.

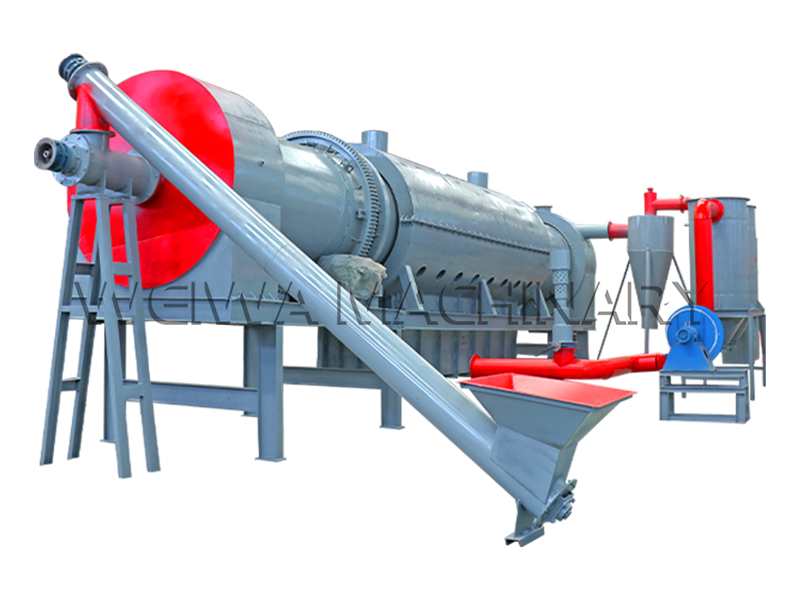

Continuous Carbonization Furnace Production Line

The Continuous Carbonization Furnace from Weiwa Machinery is designed to convert a wide range of biomass materials into high-quality charcoal in a fully automated and uninterrupted process. Compared with traditional batch-type kilns, this furnace adopts advanced continuous feeding and discharging systems, ensuring stable output, high efficiency, and reduced labor cost.

Mechanism Charcoal Making Production Line

The Mechanism Charcoal Making Production Line by Weiwa Machinery is a complete and integrated solution for producing high-quality machine-made charcoal on an industrial scale. It is designed to handle the entire process — from raw biomass preparation to final charcoal briquettes — ensuring stable performance, high efficiency, and profitable output.

Production Flow

- मुंहतोड़ – Raw materials (wood, bamboo, crop residues, नारियल के गोले, वगैरह।) are crushed into fine powder.

- सुखाने – The material is dried to achieve optimal moisture content (8–12%), ensuring high briquetting efficiency.

- कड़ा – A briquette press machine compresses the dried powder into uniform sticks or custom shapes with high density.

- अथ जलकर कोयला हो जाना – The briquettes are carbonized in a furnace, resulting in smokeless, high-strength mechanism charcoal.

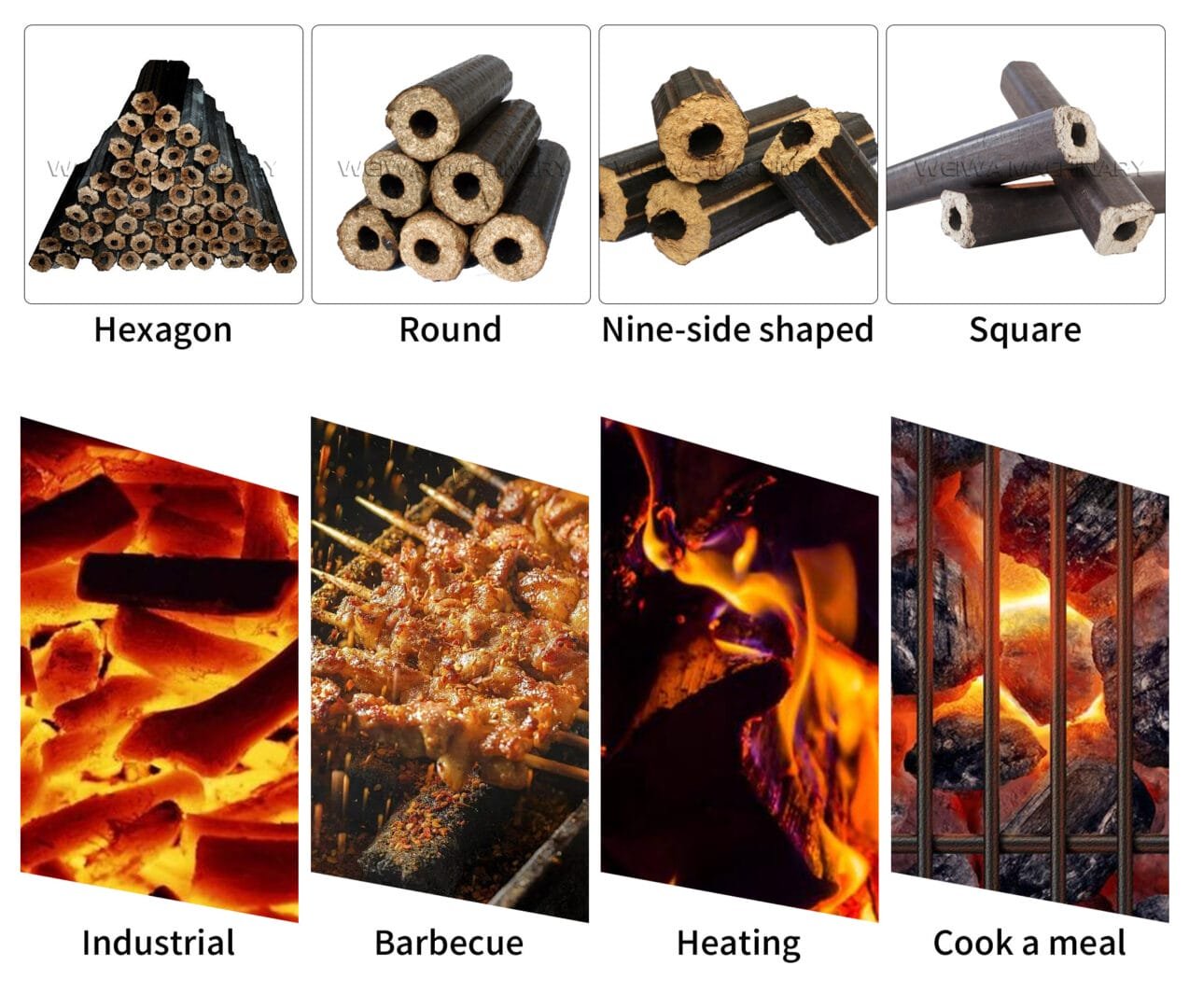

Different Shape Final Products and Their Display Effects

Key Advantages

- Complete Turnkey Solution: Covers all stages of charcoal production, reducing manual handling.

- High Output & Consistency: Ensures uniform briquette shape, घनत्व, and carbonization quality.

- Customizable: Briquette shapes and sizes can be tailored to meet different market demands.

- Energy Efficient: Recycles combustible gas for heating, lowering fuel costs.

- Commercial Value: Produces high-strength charcoal briquettes suitable for BBQ, industrial fuel, धातुकर्म, and activated carbon industries.

Applications

This production line is widely used in commercial charcoal manufacturing plants, especially where large-scale and standardized production is required. With strong adaptability and high profitability, it is the preferred choice for entrepreneurs and investors looking to enter the charcoal business

FAQ

1. What raw materials can be used in Weiwa charcoal making machines?

Our machines can process a wide range of biomass materials, including wood, bamboo, चूरा, नारियल के गोले, चावल की भूसी, crop residues, and biomass briquettes.

2. What is the difference between the Continuous Carbonization Furnace and the Horizontal Carbonization Furnace?

The continuous furnace is suitable for large-scale, uninterrupted production with higher automation, while the horizontal furnace is a batch-type solution, more cost-effective for small and medium producers.

3. How long is the service life of Weiwa charcoal making machines?

With durable steel structure and heat-resistant design, our equipment typically operates for more than 8–10 years with proper maintenance.

4. Can Weiwa provide installation and technical support overseas?

Yes. We offer professional installation guidance, प्रशिक्षण, and after-sales support to ensure smooth operation for international clients.

5. What are the applications of the final charcoal products?

The charcoal is widely used in BBQ, shisha, industrial fuel, धातुकर्म, activated carbon production, and soil improvement.

About Weiwa Machinery

Weiwa Machinery is a professional manufacturer of charcoal making machines and briquette production equipment, with years of experience serving global markets. Our product range covers निरंतर कार्बनकरण भट्ठी, क्षैतिज कार्बोज़ाइजेशन भट्टी, and Mechanism Charcoal Making Production Line, designed to meet diverse customer needs from small workshops to large industrial plants. With reliable quality, ऊर्जा दक्षता, and strong after-sales support, Weiwa has become a trusted partner for charcoal producers worldwide.

Contact Weiwa Machinery today for customized solutions and factory prices.

WeChat

WeChat

+8613838093177

+8613838093177