Introduction to Charcoal Ball Production

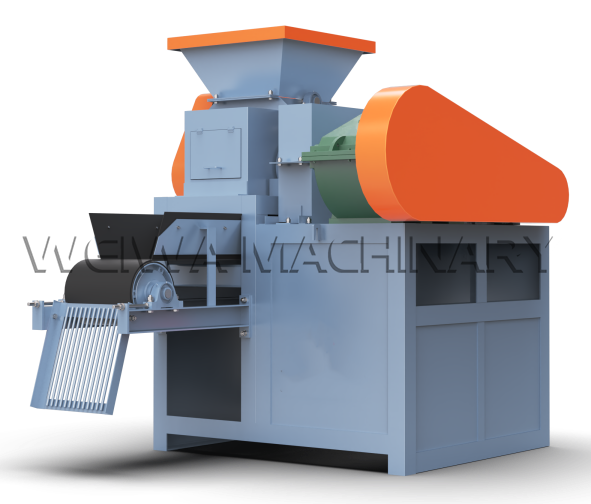

Charcoal briquettes have become a popular alternative to traditional fuel due to their efficiency, eco-friendliness, and cost-effectiveness. Among the various equipment used in charcoal production, the बॉल चारकोल ब्रिकेट मशीन (650 model) stands out for its efficiency in shaping loose charcoal powder into compact, high-density balls. परवेइवा मशीनरी, we specialize in providing reliable charcoal ball press machines that cater to diverse industrial and commercial needs.

Understanding the 650 Model Charcoal Ball Press Machine

What is a बॉल चारकोल ब्रिकेट मशीन?

दबॉल चारकोल ब्रिकेट मशीन is a mechanical press designed to compress लकड़ी का कोयला पाउडर, coal dust, or biomass materials into solid, spherical briquettes. द650 model is one of our most efficient presses, featuring a dual-roller (对辊) प्रणाली that ensures uniform pressure and high output.

Key Features of the 650 नमूना

- High Pressure & Efficiency: दdouble roller mechanism ensures consistent briquette formation with minimal waste.

- टिकाऊ निर्माण: Built with high-grade steel to withstand continuous operation.

- Adjustable Moulds: Customize briquette size (usually 20-80mm) based on your requirements.

- Energy-Saving: Requires low power consumption while maintaining high productivity.

Common Applications

- बीबीक्यू & Grilling Fuel – Charcoal balls burn longer and produce less smoke.

- Industrial Heating – Used in furnaces, boilers, and metallurgical processes.

- Agricultural Use – Soil improvement and pest control.

- Household Fuel – Clean-burning alternative to firewood.

How the 650 नमूना Charcoal Ball Press Machine Works?

HTTPS के://youtube.com/shorts/YLerBil2geE

Raw Material Preparation

Before operating the machine, ensure the raw material (लकड़ी का कोयला पाउडर, coal dust, या बायोमास) is:

- Dry (moisture content < 12%) – Excess moisture reduces binding efficiency.

- Finely Ground – Particle size should be uniform for smooth pressing.

- Properly Mixed (if using binders) – Some materials require starch, molasses, or clay as binders.

Machine Setup & Operation Steps

- इंस्टालेशन & Alignment

- Place the machine on a stable, level surface.

- Ensure the rollers are correctly aligned to prevent uneven pressure.

- Feeding the Material

- Use a vibrating feeder or manual feeding to supply material evenly.

- Avoid overfeeding, which can cause blockages.

- Adjusting Pressure & Roller Gap

- द650 model allows adjustable pressure settings for different briquette densities.

- दroller gap should be set based on the desired briquette size.

- Starting the Machine

- Power on the machine and gradually increase speed to avoid sudden load.

- Monitor the output for consistency and adjust feeding rate if needed.

- Maintenance & Troubleshooting

- Regularly clean the rollers to prevent material buildup.

- Lubricate moving parts to reduce wear and tear.

- Check for overheating – Excessive heat may indicate misalignment.

Why Choose Weiwa Machinery’s 650 नमूना?

1. सिद्ध विशेषज्ञता (30+ Years in Manufacturing)

साथ मेंover three decades of experience, Weiwa Machinery has refined its charcoal ball press machines to meet global standards. हमारा650 model is engineered for durability, efficiency, and ease of use.

2. Professional After-Sales Support

- 24/7 Technical Assistance – Our team is always ready to assist with troubleshooting.

- On-Site Training – We provide संचालन & maintenance training for your staff.

- Customized Solutions – Need a specific briquette size or material adaptation? We offer design drawings and layout planning.

3. Global Reach & Customization

Whether you need a standard 650 model or a fully customized solution, Weiwa Machinery ensures high-quality delivery and installation support worldwide.

Get Started with Weiwa Machinery Today

द650 Model Ball Charcoal Briquettes Machine is a भरोसेमंद, high-efficiency solution for turning loose charcoal powder into profitable briquettes. Whether you’re in BBQ fuel production, industrial heating, or agriculture, our machine delivers consistent performance with minimal operational challenges.

परवेइवा मशीनरी, we don’t just sell equipment—we provide complete solutions, including:

Customized Design & Planning

Professional Installation & प्रशिक्षण

Dedicated After-Sales Support

Contact us today for a quote or consultation and let us help you optimize your charcoal ball production line with our premium 650 model press machine.

के बारे में वेइवा मशीनरी

साथ में30+ years of expertise, वेइवा मशीनरी is a leading manufacturer of लकड़ी का कोयला ईट मशीनें, ball presses, and biomass equipment. हमाराprofessional after-sales team, customized solutions, and design planning services ensure seamless operations for clients worldwide. Get in touch with us for inquiries and tailored machinery solutions today.

- भीड़:+8613838093177

- Whatsapp:+8613838093177

- ई-मेल:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177