हाल के वर्षों में, as industries across India and Southeast Asia continue to grow, so does the challenge of managing industrial by-products such as coal ash. परवेइवा मशीनरी, we recently had the opportunity to test our बॉल चारकोल ब्रिकेट मशीन using fly ash samples mailed directly from a client in India. This trial not only demonstrated the adaptability and efficiency of our equipment but also highlighted the untapped potential of लकड़ी का कोयला ईट मशीनें in addressing both environmental concerns and resource optimization in the region.

Understanding the Challenges of Coal Ash in India

Coal ash is a fine powder that is a byproduct of burning pulverized coal in thermal power plants. While it is commonly used in the construction industry — especially in cement and concrete — its inconsistent quality, potential health risks, and lack of standardized processing methods make it a challenging material to manage effectively.

1. Inconsistent Material Quality

The chemical composition of fly ash can vary significantly depending on the type of coal used and the combustion technology employed. These variations directly affect its behavior during processing and its suitability for different applications. For manufacturers, this inconsistency poses a real challenge in maintaining product quality and operational efficiency.

2. Environmental and Health Concerns

Improper disposal or unregulated use of fly ash can lead to serious environmental contamination. It may contain trace amounts of heavy metals and other toxic substances. If not handled properly, these materials can leach into soil and water systems or become airborne, posing risks to both human health and ecosystems.

3. Lack of Standardized Processing Techniques

Although efforts have been made to regulate fly ash usage, the absence of universally accepted technical standards for its secondary applications often limits its integration into more innovative uses. This gap creates an opportunity for advanced machinery — like our BBQ Charcoal Briquette Machine for India — to introduce new methods of safe and efficient processing.

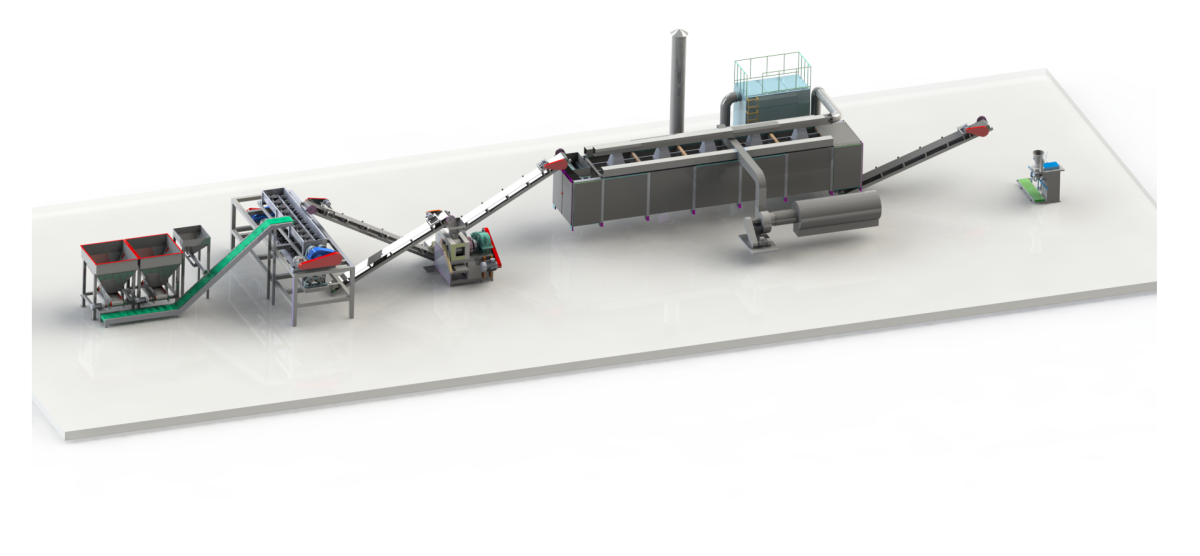

Ball Charcoal Briquettes Machine for Coal Ash Briquetting

परवेइवा मशीनरी, we developed a high-efficiency Ball Charcoal Briquettes Machine that can press coal ash into dense, uniform briquettes—either for fuel, construction, or further processing.

हाल ही में, we received coal ash samples from an Indian client and conducted a live test run to demonstrate how our machine can:

- Compact fly ash into stable briquettes (ball or column shape)

- Improve material handling & transportation

- Enable reuse in construction, energy, or industrial applications

How the Briquetting Process Works?

HTTPS के://youtu.be/PYwnFZB8NTQ

- Raw Material Preparation – The coal ash is mixed with a बांधनेवाला (if needed) to improve cohesion.

- Feeding into the Machine – The material is fed into our चारकोल ब्रिकेट मशीन (suitable for both ball and customized shapes).

- High-Pressure Compression – Our machine applies strong mechanical pressure to form durable briquettes without additives (or with minimal binders).

- सुखाने & Storage – The briquettes are then dried (if required) and stored for further use.

What is thw Result?

It is a stable, reusable product that reduces waste and creates economic value.

Why Our Ball Charcoal Briquettes Machine Is Part of the Solution?

At Weiwa Machinery, we’ve developed a range of लकड़ी का कोयला ईट मशीनें designed to transform loose, powdery, or irregularly shaped raw materials into compact, uniform, and easy-to-handle briquettes. When we received a shipment of fly ash from our Indian client, we saw it as the perfect opportunity to test how our ball-type briquette press would perform under real-world conditions using materials sourced directly from the target market.

1. Efficient Briquetting of Coal Ash

हमाराबॉल चारकोल ब्रिकेट मशीन was able to compress the fly ash into dense, spherical briquettes with minimal binder requirements. This is especially important when working with low-cost or waste-derived materials, as it helps maintain a favorable cost-to-output ratio. The machine’s robust design ensured smooth operation even with the slightly abrasive nature of the fly ash.

2. Versatility Across Applications

While fly ash is not traditionally used for fuel, the briquettes produced in our trial can potentially be used in applications such as alternative fuel sources, construction additives, or even as raw materials in industrial furnaces — depending on further treatment and local regulatory acceptance. This versatility opens multiple pathways for monetizing what was previously considered waste.

3. Adaptable to Local Conditions

India’s infrastructure and industrial landscape present unique challenges, from inconsistent power supply to varying levels of technical expertise. हमाराcharcoal briquette machine product line is engineered to be durable, easy to operate, and adaptable to a wide range of environments — making it an ideal solution for clients in India and across Southeast Asia.

The Broader Value of Briquetting Technology in India

Beyond our successful coal ash trial, it’s important to understand the broader role that ब्रिकेटिंग मशीनें — especially ball-type charcoal briquette plants — can play in supporting sustainable development in India.

1. Promoting Resource Efficiency

भारत, like many rapidly developing nations, faces increasing pressure on its natural resources. By converting waste materials like fly ash into usable briquettes, briquetting technology enables more efficient use of resources and reduces dependency on virgin raw materials. This contributes to a more circular economy and helps conserve natural reserves.

2. Enhancing Material Performance

In certain applications, fly ash briquettes — especially when combined with other materials — can enhance the performance of end products. For example, in the construction industry, fly ash is known to improve the strength and durability of concrete. By producing it in a controlled, briquetted form, manufacturers can ensure more consistent integration into their processes.

3. Generating Economic Value

One of the most immediate benefits of briquetting is the creation of economic value from waste. By transforming low-cost or free raw materials into marketable products, businesses can reduce their production costs, improve margins, and create new revenue streams. This is particularly relevant for small and medium enterprises in India looking to improve competitiveness without significant capital investment.

The Market Potential for Charcoal Briquette Machines in India and Southeast Asia

India’s growing population, expanding industrial base, and increasing focus on sustainability create a fertile ground for technologies like our BBQ Charcoal Briquette Machine for India. As the country continues to seek solutions for waste management, ऊर्जा दक्षता, and industrial innovation, the demand for reliable, कुशल, and customizable briquetting equipment is set to rise.

Southeast Asia, too, presents significant opportunities. Countries like Vietnam, इंडोनेशिया, and the Philippines are experiencing similar challenges with industrial waste and are actively seeking technologies that can support both environmental goals and economic growth. हमाराball charcoal briquette plant in India model can be easily adapted to meet the specific needs of these markets, offering a scalable and flexible solution.

Customized Solutions and Local Support from Weiwa Machinery

At Weiwa Machinery, we understand that every client has unique needs. That’s why we offer customized designs, detailed planning for site layouts, and tailored machinery configurations to ensure that our equipment integrates seamlessly into your operations. Whether you’re working with fly ash, बायोमास, लकड़ी का कोयला, or other raw materials, our team is equipped to deliver a solution that works for you.

Our experience spans over 30 years in the design and manufacturing of briquetting machinery. We pride ourselves not only on the quality of our equipment but also on our professional after-sales support, responsive customer service, and commitment to client success. When you partner with Weiwa, you’re not just buying a machine — you’re gaining a dedicated ally in your production journey.

A Sustainable Future Starts with Efficient Processing

The successful test of our बॉल चारकोल ब्रिकेट मशीन using Indian-sourced fly ash is more than just a technical achievement — it’s a demonstration of the transformative potential of briquetting technology. By turning a challenging waste material into a usable, potentially valuable product, we’re not only helping our clients improve their operations but also contributing to a more sustainable and resource-efficient future.

For businesses in India and across Southeast Asia looking to explore the benefits of briquetting, Weiwa Machinery offers the expertise, equipment, and support you need to get started. From charcoal briquette machine product lines to complete ball charcoal briquette plants, we have the solutions to match your vision.

Contact Weiwa Machinery today to learn more about our equipment, request a quote, or discuss how we can help you bring your project to life. Let’s build a cleaner, greener, and more efficient future — together.

के बारे में वेइवा मशीनरी

ओवर के साथ30 वर्षों का अनुभव in the manufacturing of briquetting machinery, Weiwa Machinery has established itself as a trusted name in the industry. We specialize in designing and producing high-quality लकड़ी का कोयला ईट मशीनें, ball briquette presses, and complete briquette production lines tailored to meet the diverse needs of our global clientele. Our team of experts provides professional after-sales service, customized design solutions, औरon-site planning support to ensure seamless installation and operation. Whether you’re processing biomass, लकड़ी का कोयला, or industrial by-products like fly ash, Weiwa Machinery is your partner in innovation and sustainability. Contact us today to learn more or to request a personalized consultation.

WeChat

WeChat

+8613838093177

+8613838093177