Witnessing Our Sawdust Extruder Machine Head to the Philippines

This month, the production floor at Weiwa Machinery was buzzing with excitement as our latest चूरा निकालने की मशीन—a core component of a complete sawdust briquette machine production line—was carefully packaged and prepared for shipment to the Philippines. This isn’t just another delivery; it’s a testament to the growing demand for sustainable charcoal solutions in Southeast Asia, where our Philippine client is investing in a local production facility to convert agricultural waste (primarily sawdust) into high-quality briquettes.

As the machine rolled onto the container, wrapped in protective film and secured with steel frames, our team reflected on the months of collaboration with the client. From initial consultations about their raw material characteristics (mostly mixed hardwood sawdust from local furniture manufacturers) to customizing the चूरा ब्रिकेटिंग मशीन’s pressure settings and briquette diameter (60मिमी, tailored for their market’s preference), every detail was engineered to ensure efficiency and durability in the Philippine climate.

Why the Philippines Needs Sawdust Briquette Machines?

The Philippines, with its vast forestry and woodworking industries, generates significant amounts of sawdust as a byproduct—often discarded or burned, contributing to air pollution and wasted resources. Meanwhile, the demand for clean-burning charcoal (for household cooking, restaurants, and even industrial use) remains high, especially in urban areas where LPG prices fluctuate.

Sawdust briquettes, produced using our चूरा बाहर निकालना और briquetting machine, offer a sustainable alternative. These briquettes are made by compressing sawdust without additives, relying solely on the natural lignin in wood to bind the particles when heated. नतीजा? A dense, uniform fuel that burns longer than traditional lump charcoal, produces less smoke, and is cheaper to produce locally.

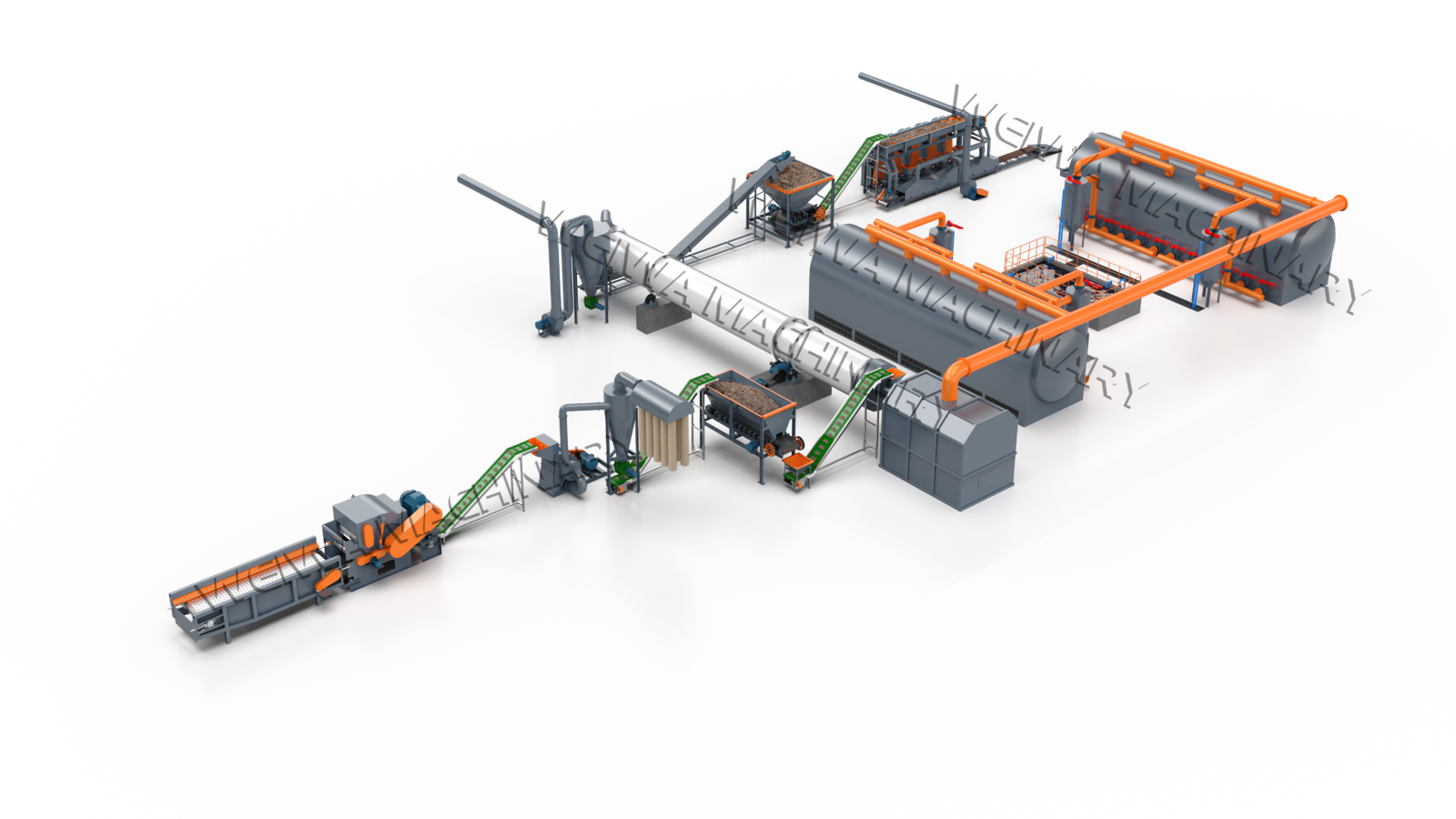

For our Philippine client, the goal is twofold: reduce waste from local sawmills and furniture workshops while creating a profitable business selling briquettes to nearby markets. हमाराsawdust briquette machine production line—which includes shredders, dryers (if needed), the sawdust extruder machine, and the final briquetting unit—is designed to handle their specific input (moisture content ~12-15%, particle size <5मिमी) and output up to 800kg of briquettes per hour.

How Our Sawdust Extruder Machine Works?

At the core of our solution is the sawdust extruder machine—a piece of equipment that transforms loose sawdust into dense, cylindrical “green briquettes” ready for carbonization (or direct use, depending on the process). Here’s how it works:

The Role of the Extruder in Briquette Formation

Unlike traditional sawdust briquetting machines that use a piston or screw to compress sawdust directly, our extruder employs a high-pressure screw mechanism to first form a compact “briquette core.” The sawdust is fed into the machine’s hopper, where it’s pushed through a heated barrel by a rotating screw. The heat (typically 80-120°C) softens the lignin in the wood fibers, acting as a natural binder. As the material moves forward, the increasing pressure compresses it into a dense rod, which is then cut into uniform lengths (usually 40-60mm).

This pre-compacted form is ideal for the next stage: अथ जलकर कोयला हो जाना (if making charcoal briquettes) or direct use as biomass fuel. For the Philippine client, we recommended the extruder because it allows for higher throughput (up to 1 ton/hour) and produces briquettes with consistent density, reducing breakage during handling.

Customization for Local Materials

One of the challenges in the Philippines is the variability of sawdust—some sources have higher resin content (from pine or tropical hardwoods), which can affect binding. Our engineers adjusted the extruder’s screw pitch and heating zones to accommodate these variations, ensuring stable performance even with mixed sawdust. Additionally, the machine’s stainless-steel construction resists corrosion in humid environments, a common issue in coastal Philippine cities.

What Happens Next in the Philippines?

Once the container arrives in Manila, our Philippine partner will unload the sawdust extruder machine and other components (including the dryer, conveyor belts, and control panels) and begin installation at their factory site. Here’s what the next steps look like:

Our team will provide remote training via video calls, guiding the operators on how to feed sawdust evenly, monitor the extruder’s temperature and pressure gauges, and troubleshoot common issues (like blockages or uneven briquette size). We’ll also share a detailed manual translated into Tagalog, covering maintenance schedules (जैसे, lubricating the screw every 50 घंटे, checking the heating elements monthly) और सुरक्षा प्रोटोकॉल.

अंदर 2-3 weeks, the entire sawdust briquette machine production line will be operational. The client plans to start with sawdust from nearby furniture factories, gradually expanding to include sawmill waste as their supply chain grows. Their target market includes local sari-sari stores (small retail shops), restaurants, and households looking for affordable, smoke-free charcoal alternatives.

Our Expertise in Charcoal Solutions

बायोमास प्रसंस्करण उपकरणों के प्रमुख निर्माता के रूप में, Weiwa Machinery has been specializing in चूरा ईट मशीनें और sawdust extruder machines for over 15 years. Our reputation is built on three pillars:

1. Customization for Local Needs: We don’t offer one-size-fits-all solutions. Every चूरा ब्रिकेटिंग मशीन we sell is tailored to the client’s raw materials (moisture content, particle size, type of wood), production capacity, and end-use (charcoal vs. biomass fuel). For the Philippine project, we adjusted the extruder’s parameters based on their specific sawdust characteristics and market preferences.

2. End-to-End Support: From design consultation to installation and training, our team works closely with clients to ensure smooth operation. We also provide spare parts and technical support for years after the sale, reducing downtime and maximizing ROI.

3. सिद्ध पिछली उपलब्धियाँ: Our machines have been exported to over 50 देशों, including Vietnam, इंडोनेशिया, Nigeria, and now the Philippines. Clients consistently praise the durability of our sawdust extruder machines (many operate for 8+ years with proper maintenance) and the high quality of the briquettes they produce.

Sustainable Charcoal Production in Southeast Asia

हमारा शिपमेंटचूरा निकालने की मशीन to the Philippines is more than a business transaction—it’s part of a larger movement toward sustainable energy. By converting waste sawdust into valuable briquettes, our client is not only reducing environmental pollution but also creating jobs and providing a cleaner cooking fuel for their community.

As more countries in Southeast Asia (and globally) recognize the potential of biomass waste, we at Weiwa Machinery are committed to innovating and delivering equipment that makes this transition easier. Whether you’re a small workshop looking to recycle your sawdust or a large-scale producer aiming to enter the charcoal market, our sawdust briquette machine solutions are designed to grow with you.

के बारे में वेइवा मशीनरी

Founded in 1990, Weiwa Machinery is a trusted Chinese manufacturer specializing in चूरा ईट मशीनें, sawdust extruder machines, and complete biomass processing lines. With a factory spanning 2000 square meters and a R&D team of over 30 engineers, we focus on designing high-efficiency, low-maintenance equipment tailored to diverse raw materials and production needs.

Our products have been exported to 50+ देशों, serving clients in agriculture, forestry, and renewable energy sectors. Beyond equipment sales, we provide installation guidance, operator training, and long-term technical support to ensure your success.

If you’re interested in learning more about our चूरा ब्रिकेटिंग मशीन solutions or have a project in mind, contact us today—we’d love to help you turn waste into value.

WeChat

WeChat

+8613838093177

+8613838093177